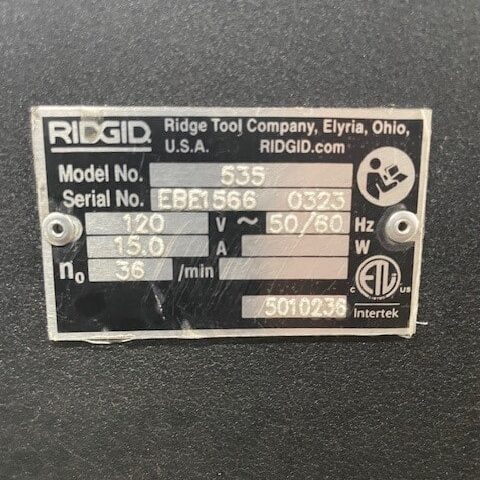

Ridgid 535 Series Pipe Threader

This product has been sold.

The Model 535 threading machine pipe threader maintains the ruggedness of the industry workhorse while adding the features that makes the threading operation more productive. A large chip tray and oil reservoir makes the 535 ideal for longer uninterrupted threading. The 535 is designed around maximum uptime with the upgrades that matter most to the pipe working professional. Users also benefit from the part commonality between the 535, the 535A Automatic and other RIDGID® equipment.

Specifications:

- Pipe Capacity: 1/8″-2″ (3mm-50mm).

- Bolt Capacity: 1/4″-2″ (6mm-50mm).

- Switches: Forward/off/reverse and integral foot switch.

- Chuck: Speed Chuck with three replaceable rocker-action jaw inserts.

- Rear Centering Device: Cam-action, turns with chuck

- Cutters: Self-centering, full-floating. Two models available: Standard Model 820 Wheel-Type Cutter, pipe capacity 1/8″-2″ (3mm-50mm), bolt capacity 1/4″-1″ (6mm-25mm). Optional Model 821 Blade-Type cutter, pipe capacity 1/2″-2″ (12mm-50mm). See ordering chart.

- Reamer: 5-flute cone, RH, 1/8″-2″ (3mm-50mm).

- Oil pump: Self-priming gerotor oil pump.

- Reamers: RH / LH combination reamer available.

Features:

- Large 1.75 gallon (6.6 L) oil tray.

- Large chip tray.

- Generous top cover for keeping tools and fittings handy.

- High clearance carriage makes threading easier.

- Speed chuck with rocker-action jaws centers and grips work piece instantly.

- Can be used with geared Models 141 and 161 threaders.

- Uses Model 816/817 semiautomatic, Model 815A self-opening or Model 811A quick-opening die heads.

- Length gauge for quick, accurate cut-off.

Browse Equipment

- Air Compressors & Tanks

- Cement, Grout & Shotcrete Equipment

- Electrical Equipment & Components

- Enerpac/Simplex Hydraulic Equipment

- Equipment Attachments

- Equipment Parts

- Equipment Retrieval Kit

- Generators

- Greenlee Equipment

- Heaters

- Heavy Equipment

- Hydraulic Power Equipment

- Lifting, Rigging & Hoisting Equipment

- Light Duty Vehicles

- Lighting

- Material Handling & Personnel Baskets

- Miscellaneous

- Pipeline Equipment

- Pumps

- Rail Car Handling

- Reeling/Tensioning Machines & Stands

- Roadheaders

- Rock Drills & Accessories

- Rock Splitters / Breakers

- Safety Equipment

- Scooptrams

- Sheaves

- Skid Shacks

- Slushers

- Test Weights

- Trailers

- Underground Ready Skids/Trailers

- Underground Ready Vehicles

- Ventilation

- Welding Equipment

- Winches